A new Rankin dinghy

by Owen O’Connell

Continuing from part 1 🔗 describing significant milestones in building the new Rankin dinghy.

May 7, 2021

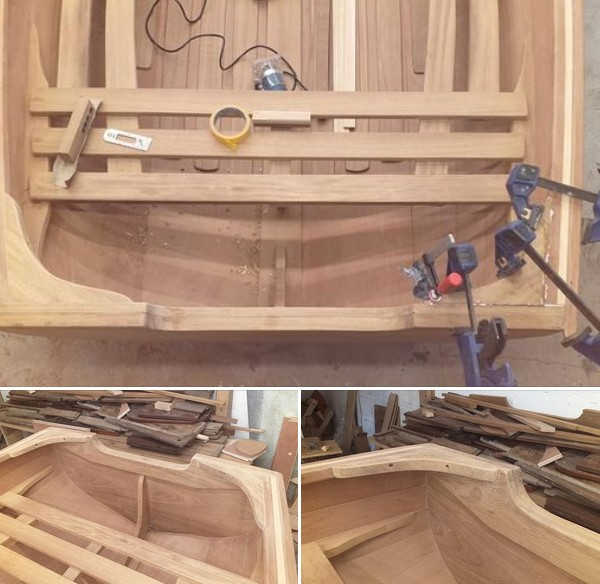

Having made the templates for the aft seat assembly the next task is to rough cut out the Iroko close to the line and finish off the pieces on the router table.

May 9, 2021

The consensus was to use a stringer under the side seats (as per the early rankins) for support rather than the “ hourglass” support (seen on most of the later Rankins. This was done by making a concave jig to match the seat profile then gluing and screwing a length of 38x18 Siberian Larch in place.

May 10, 2021

All the pieces of the stern seat assembly were laid in the jig, glued and screwed, (the yellow pvc tape was to protect the wood from glue seepage) After 24 hrs the assembly was removed from the jig and cleaned down ( the pvc tape was not the best).

May 11, 2021

All 6 seat supports made using template and router. One edge was then beveled to match the inside curve of the hull while ensuring the top surface remained on the same plane as its opposite number on the other side of the boat. Extra long rebar clamps are used to hold the piece in place while checking the fit.

May 18, 2021

Following glue clean up on the underside of the seat supports, the shell was turned ( Maurice lending a hand) and the aft seat assembly was screwed and glued down, the forward seat is screwed only as it needs to be removed when we come to fit the dagger board box.

May 20, 2021

Working on the struts that support the triangular shaped floorboard and shaping the pieces that make up the daggerboard box using templates and router.

May 23, 2021

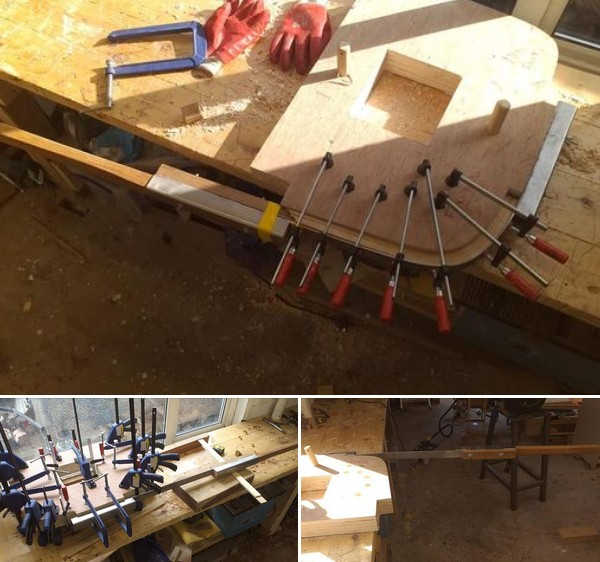

Working on making up the daggerboard box, the stiffners on the top and bottom of the “box” kindly milled to size by James Burke, the plastic is to ensure the two sides are no glued together prematurely before a melamine liner is glued to the inside faces of the “box”.

May 27, 2021

Dry fitting and fairing the box to the hog before unscrewing the two halves of the box and glueing the melamine lining to the inside of the box. It’s done in this sequence as the melamine protrudes below the box by the thickness of the hog and keel and therefore would be vulnerable while fairing.

June 4, 2021

It’s official! The Rankin Dave O’Keeffe and myself are building is a sailing dinghy. Daggerboard box and mast thwart glued and screwed in place today.

June 9, 2021

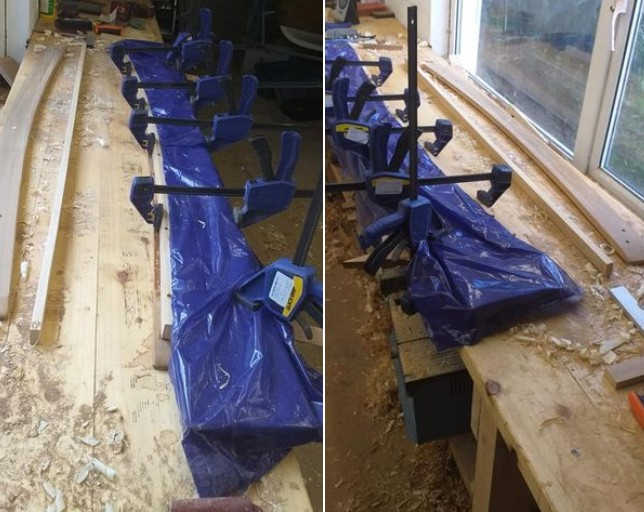

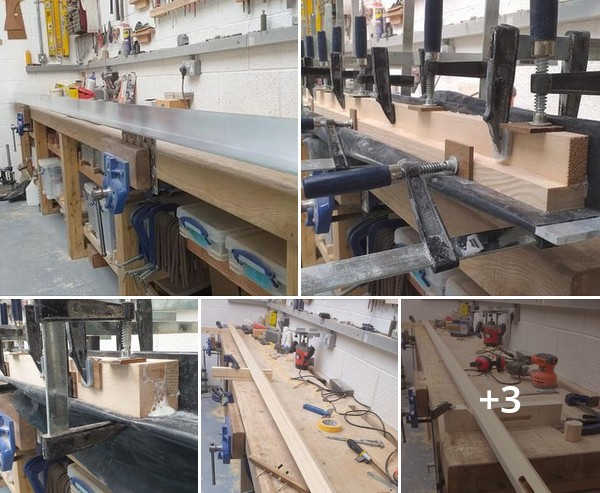

Today the Dinosaur was put through its paces as Dave O’Keeffe and myself bent, glued and clamped lengths of Sepele and Siberian Larch over its back to form the gunnels.

June 10, 2021

Our full stock of 25 clamps was used to hold the 1st of the gunnels in place today.

June 16, 2021

Both inwales fitted with the top strake planed to the sheer. Outwales milled to 20 x 25mm and ready for fitting. (its all gunnels to me!)

June 25, 2021

The frist of the Iroko floorboards (8mm thick) glued in place, the yellow spacer is used to maintain the gap between the floorboards.

June 28, 2021

Half way there - four floorboards (bottom boards) in and four more to go.

July 4, 2021

All eight bottom boards now in, only 28 more pieces to be fitted and glued in place. Can you identify them?

July 8, 2021

Spot the difference between this and the last post

July 9, 2021

Chainplates fitted today and getting on with cutting up an ex wardrobe to make the forward floorboards.

July 20, 2021

Completed the forward set of floor boards today. The wood Honduras Mahogany is courtesy of Eddie English and came in the form of an ex wardrobe.

July 22, 2021

One of those jobs that makes a rankin a Rankin.

Aug 10, 2021

Gunnels fitted with Dave O’Keeffe, wardrobe varnished and the two midship knees also fitted.

Aug 30, 2021

The quarter knees were fitted today using Iroko. Our first choice, white oak was scuppered by a very cantankerous bandsaw.

Aug 31, 2021

Setting up the rollock plates; two concentric holes are required, one 21mm diameter to take the circular casting and another 14mm to take the 13mm diameter rollock shaft; the plate still needs to be sunk flush with the gunnel.

Sept 1, 2021

All four rollock plates now rebated flush to the gunnel and the mast step cut into the forward thwart using a router.

Sept 6, 2021

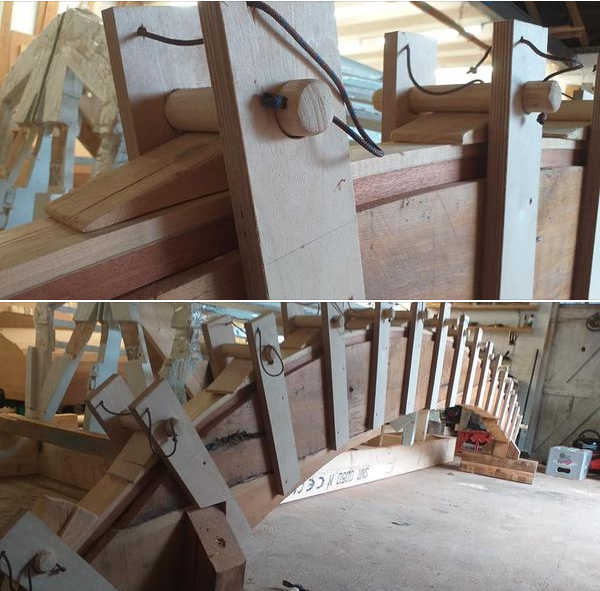

Final assembly of the bending jig for the laminated knees this morning and a test run this afternoon using Siberian Larch.

Sept 14, 2021

Making up the breasthook took more than one go to get right, but now it’s glued, fitted and shaped in with the stem and apron.

Sept 21, 2021

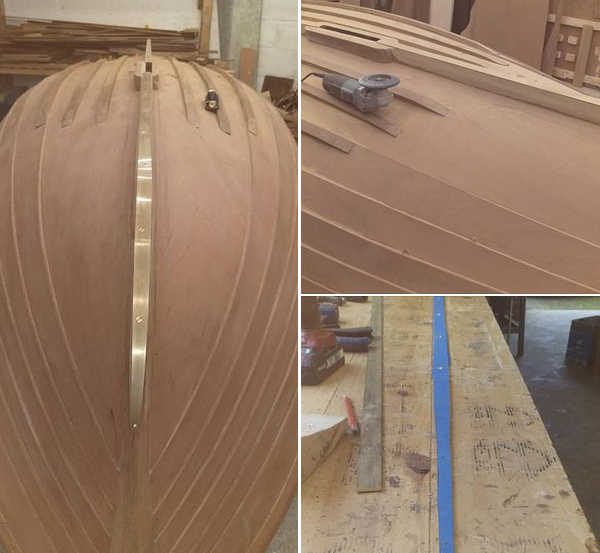

A 25mm wide brass keel band tapered to 10mm at the stem was fitted and temporarily screwed in place. The keel itself was tapered down from its max width of 40mm to match the width of the brass band.

Sept 24, 2021

With the end of the woodwork in sight and the keel band fully fitted, it was a good time to rub down and fair the hull, before preparing the shed for the next phase.

Sept 25, 2021

First of two sealer varnish coats overlapping the waterline.

Oct 2, 2021

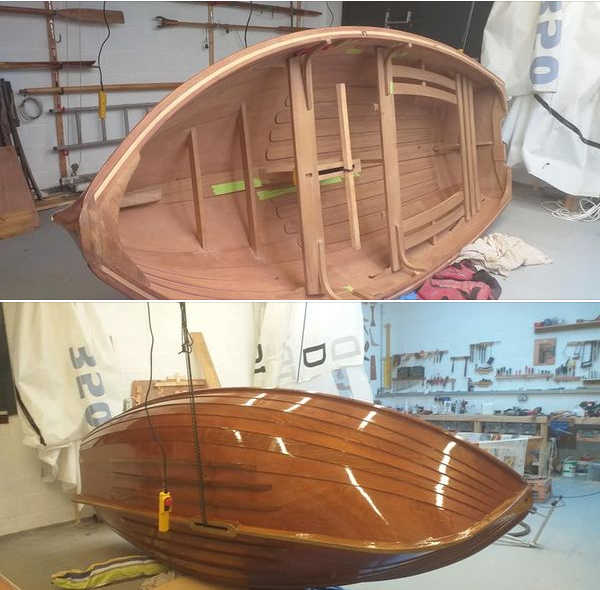

Following a change of plan and seven build coats of Epfanes Rapid Clear varnish, the hull is ready to receive three top coats of Epfanes Clear varnish.

Oct 9, 2021

Having completed the varnish and refixed the keel band (bedded in Sikaflex), MK was on hand to turn the boat and chew the cud.

Oct 14, 2021

The last laminated knee is glued up and held in place by the bending jig, while some glue lines are taped in readiness of a tidy up.

Dec 3, 2021

The last two laminated knees glued in place and cleaned off, which completes the woodwork.

Jan 31, 2022

New shed - making good the glue lines where required before the vanishing starts. The boat is tipped over to allow the epoxy to flow into the joint between the hog and garboard.

Feb 23, 2022

Last few jobs before the “sink test” - taped the margins of the bottom boards and forward floor boards, applied anti-skid coat of varnish and removed after. Also fixed the bronze rowlock plates in the gunnels.

April 1, 2022

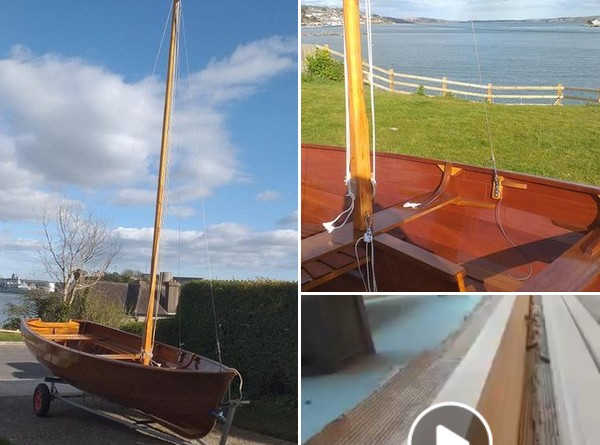

Setting up the standing rigging using R13’s mast as a template, and as luck would have it, the Sitka Spruce stock was delivered, enough for three sets of spars.

April 9, 2022

Maiden sail today for R61 - the completion of a year long journey - photo courtesy of Adrian O’Donovan.

May 11, 2022

Mast building.

Nov 17, 2022

Seats for small children as requested by new owner.